Bigger change can greatly influence and lower the quality in FDM 3D printing. Our experience shows that there’s a safe margin of about 10 degrees Celsius for lowering and raising the temperature of the extruded filament. These vary depending on the manufacturer, so it’s always wise to check the exact recommendations on the packaging. Every material has a recommended extrusion temperature, for example, ABS melts best around 240 degrees Celsius while PLA at about 200 degrees Celsius. Quality in FDM 3D printing often depends on the temperature set for extruding or on the heated platform. This seasons the extruder and the nozzle in order to keep them both in peak condition. Sponge in the filter clears the dust from the material while at the same time lubricates the filament with canola or standard mineral oil (in fact, some filaments already have it in them).

#SIMPLIFY 3D CRACK CLEAN PROFESSIONAL#

Some people consider it being an urban legend, but many professional users recommend adding filament filters to clean and oil the materials. Using airtight containers or plastic IKEA boxes with moisture absorbers inside for storage could be a good idea here.

#SIMPLIFY 3D CRACK CLEAN FREE#

It should be free of excessive humidity or else your materials could go stale and lose some of their properties, like durability.

Whenever you store larger quantities of filaments, remember to provide a suitable storage space. Knots and breaks on the thread may block the flow of the filament into the extruder or clog it causing, even more, damage. It’s very important to make sure that the filament is properly wound onto the spool. This first one may sound like a no-brainer, but a lot of people forget about taking proper care of their filaments, which can influence the entire 3D printing process. We hope they’ll help you in achieving the best possible quality of your prints. We gathered a set of tips and pieces of advice based on our experience with 3D printing in general and using ZMorph multitool 3D printer in particular. A lot depends not only on the 3D model you’re trying to manufacture, but also from various settings and environmental factors related to the machine itself, its properties and technical condition.

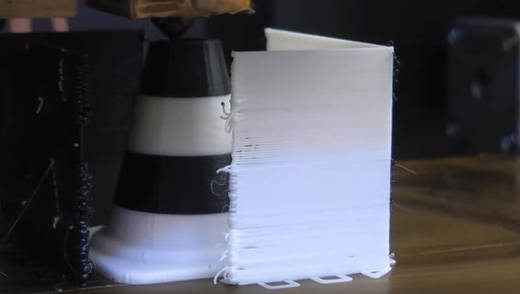

We have to admit, we try to avoid support where we can, and where we can’t we just pick one of the stock Cura settings. 5 dense layers at 90% 0 gap layers top or bottom.Support material every other layer, 15% crossing at -45, and 45.We finally found a Reddit post that gives the recipe for Simplify 3D: We had to dig a little further to find out how he did it. We saw the video below and we have to admit that it did remind us of a brick of uncooked ramen noodles. While ramen support might sound like a help desk for soup, it is actually a technique uses to get easy-to-remove support structures on 3D prints.

0 kommentar(er)

0 kommentar(er)